Close search

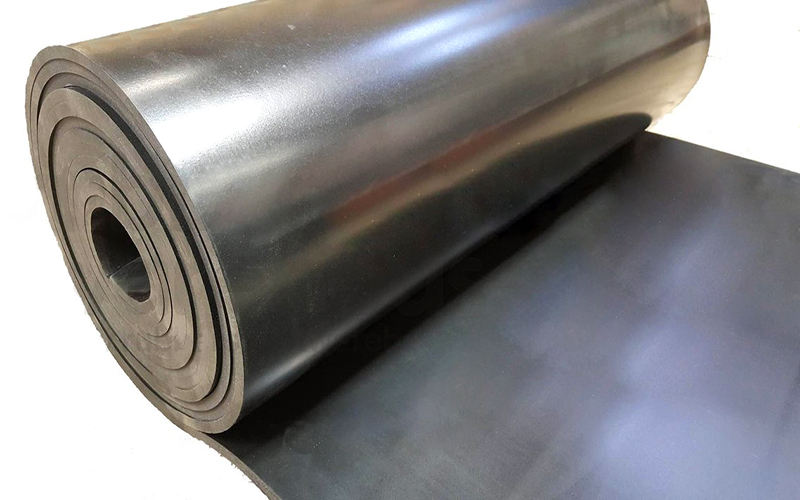

Categories: High-End Rubber Material Viton Rubber Products

GBL-600S Viton Rubber exhibits rapid curing, excellent mold release, and anti-contamination properties. It also demonstrates outstanding resistance to permanent compression deformation without the need for post-curing or with short post-curing times. These characteristics make it perform well in the mentioned application areas. Here are some key characteristics of the GBL-600S:

> Chemical Composition: It’s a copolymer of hexafluoropropylene, vinylidene fluoride, and tetrafluoroethylene with a cure site monomer.

> Appearance: It has an off-white color without carbon black.

> Mooney Viscosity: ML 1 + 10 at 121 °C (250 °F) is 65, indicating its flow properties under pressure. Specific Gravity: It has a specific gravity of 1.84.

> Fluorine Content: Approximately 68%, which contributes to its chemical resistance.

> Storage Stability: The product has excellent storage stability.

DUPONT GBL-600S VITON RUBBER

SPECIFICATION

Features: This product has a very fast cure rate, achieving a high state of cure. It shows improved mold release/mold fouling characteristics compared to Viton™ GBL-200. It also exhibits improved mold flow, lower shear sensitivity, and lower extrusion die swell for a 65 Mooney FKM.

Physical Properties: The GBL-600S has excellent physical properties, with high elongation both initially and after aging. It has similar resistance to heat, fluids, and low temperatures as Viton™ GBL-200.

Compression Set Resistance: It has excellent resistance to compression set, whether it’s a short-term (2 hours) post-cure or without post-cure.

The GBL-600S Viton Rubber is a high-viscosity peroxide-cured fluoropolymer adhesive with excellent low-temperature performance and improved resistance to automotive lubricants and fluids. Its application areas include:

> Engine crankshaft and camshaft rubber seals.

> Valve stem and cover elastomeric seals

> Turbocharger hoses

> Fuel injector O-rings

> Intake manifold gaskets

> Gaskets, O-rings, diaphragms, and rubber components

> Molded parts requiring low-temperature flexibility

It’s designed for easy processing and cures exceptionally fast to a high state of cure. It also exhibits improved mold release and mold fouling properties compared to other grades. The GBL-600S is recommended for applications requiring high elongation, both original and aged, and it exhibits similar heat, fluids, and low-temperature resistance compared to other Viton™ grades.

All-around rubber solutions, including product R&D, product design, material recommendation, customized and service.

The original equipment designer and raw material holder for the current industrial fields.

We have an own new materials subordinate institute. We regularly cooperate with universities to analyze and research new materials.

Please refer to the download center for getting the specific physical performance data for this product item.