Close search

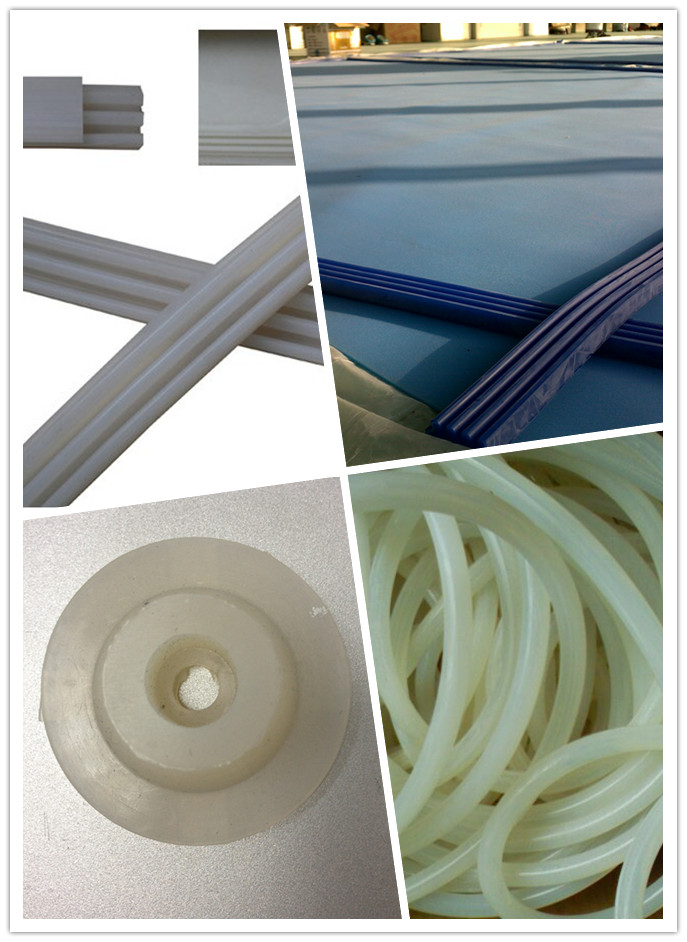

Categories: Silicone Membrane

> Three different grades of tear resistance are available.

> Silicone mountain shaped seal strip are available for edge of vacuum bag.

> High temperature resistance to 250℃, Great aging-resistance and resistance to EVA.

>Maximum widths up to 3800mm are available without joining.

>No bubbles or opaqueness are noted in the spacer in any of the laminated glass samples tested.

>Connecting vacuum pump, pump out the air and keep air pressure well in lamination.

Technical index of silicone vacuum bag:

Model No. Tensile Strength Tear Strength Hardness Elongation Common Color Common Surface KS-EXS P116 6.5 26 55±5 450 Semi-Transparent/Blue Textured/Smooth KS-EXS Z117 8 32 55±5 650 Semi-Transparent/Blue Textured/Smooth KS-EXS G118 9.5 40 55±5 750 Transparent/Grey/Blue Smooth/Smooth

(MPa)

(N/mm)

(Shore A)

(%)

Silicone vacuum bag helps to pump out the air between glass and EVA film, will fix the two glass on the right position to avoid the error. Besides, after fixing the glass, it is useful for the glue adhesion when the EVA film start to melt. It is high heat-resistance and tear-resistance. Each bag includes silicone sheet, buckle and nozzle, tube and other accessories.

Top and bottom pad edges are specially designed, providing an airtight interlocking system. The higher the vacuum in between the top and bottom pads, the firmer the edges are sealed.

This strong silicone pad meets the most severe industrial tests. It is made of special high temperature resistant silicon. The material will not become brittle after numerous heating and cooling cycles. It is resistant to high pressure forces when wrapping around glass during vacuum.

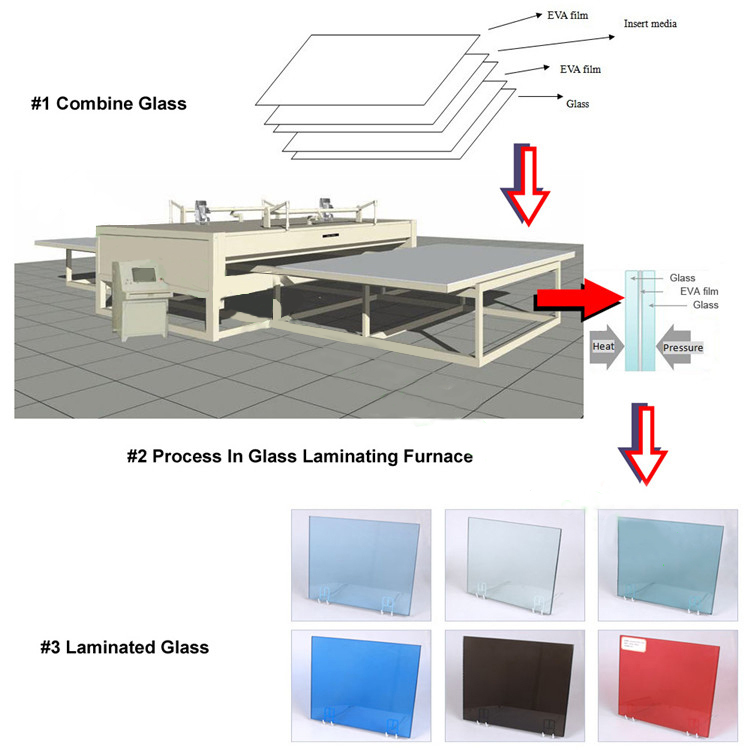

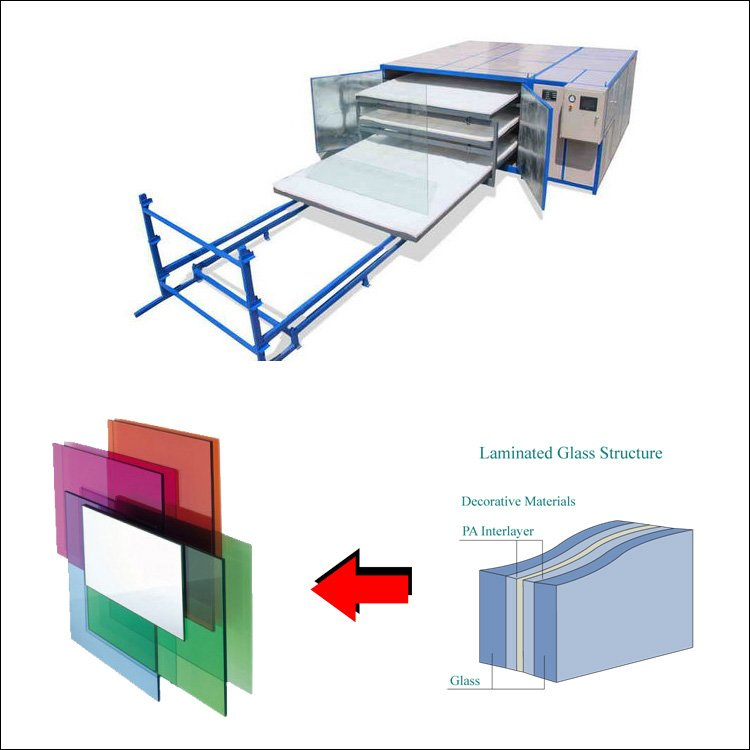

Laminated glass vacuum furnace is a special equipment that adopted the vacuum principle, make the glass heated under vacuum conditions, using atmospheric pressure inside the vacuum bag glass pressurized air leaving it unable to rule out the bubbles, while heating under vacuum in the vacuum conditions, the two or more pieces of glass, EVA (or other membrane) heat together to make glass compression, let the EVA film melt under high temperature condition, then can be that let the laminated materials (such as silk, and paper, cloth, drawing paper, etc.) and glass glue together firmly, to form a whole-part, To achieve the purpose of explosion protection, security, decorative and practical. As the core component of Laminated glass reinforced furnace, the vacuum bag affects the quality of the glass products. Products are mainly used to strengthen the glass, sliding door glass, laminated safety glass for vacuum using.

Laminated glass vacuum bag is mainly used for enhanced in laminated glass reinforced furnace, laminated glass is a kind of good performance of safety glass, it is made of two or more pieces of glass with a EVA film in the middle of the glass, through the appropriate machinery for processing & machining, to make glass with strong adhesive glue to be one product. It has transparent, light resistant, heat resisting, cold resistant, high mechanical strength, and so on performance. When the outer glass was broken by the impact force, its fragments firmly adhesive membrane in the middle, not easy to hurt people, just enter into radial crack, also can maintain its original shape and visibility, in a certain period of time, can continue to use. Thus it can guarantee the safety of the human body. And effectively play the role of the effect of anti-explosion & bulletproof, the people have been widely used in automobiles, trains, planes and other means of transport. Because it has the security effect of explosion-proof, bullet-proof, in recent years it is widely used in high-rise buildings, Banks, and need to bulletproof, explosion-proof, guard against theft, guard against leaks, and other important occasions. But the silicone vacuum bag quality directly affects the quality of the laminated glass.

CASIS production of silicone sheet is according to the different requirements of users can be divided into ordinary silicone sheet and high tear resistance silicone vacuum bags. Laminated glass silicone vacuum bag without joining together is my biggest advantage, make the whole thickness of piece of silicone sheet to be more symmetrical, Make air tightness of our products is better, the tear strength is higher, long time using life, and ensure the quality of the glass.